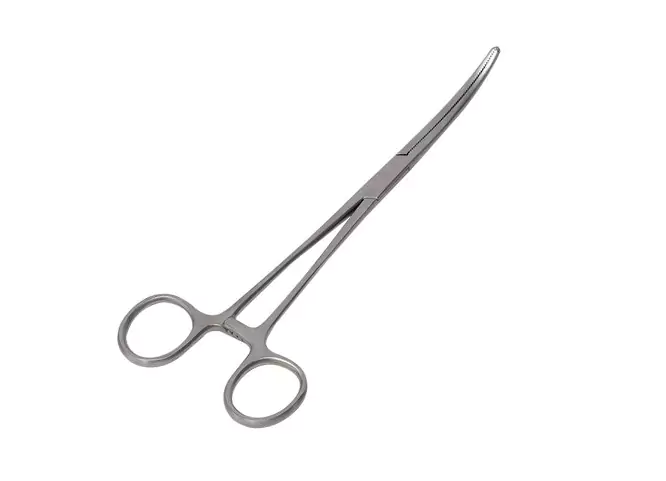

Fishing forceps are specialized tools designed for precise tasks in fishing, such as removing hooks, handling lines, and cutting leaders. They provide anglers with a secure grip and accurate control in various fishing conditions.

RTI manufactures professional-grade fishing forceps using high-quality stainless steel that resists corrosion in both fresh and saltwater environments. Our products feature ergonomic handles, reliable jaws, and versatile designs suitable for different fishing applications. We focus on durability, functionality, and user comfort.

As a leading Chinese manufacturer, we offer OEM customization, bulk order options, and wholesale pricing. Our factory delivers consistent quality, on-time shipments, and custom branding solutions for distributors and fishing brands worldwide. Partner with RTI for reliable fishing tool supply.

Match Forceps to Target Fish:

Different fish species require different forceps. For example, long-nose forceps work better for toothy species like pike, while shorter models are sufficient for trout and panfish.

Consider Fishing Environment:

Saltwater anglers need heavier-duty, corrosion-resistant tools, while freshwater anglers can often use lighter models. Choosing according to environment extends tool life.

Check Jaw Strength and Locking:

For anglers dealing with strong leaders or deep-hooked fish, jaw strength and a reliable locking system are important to prevent slipping.

Evaluate Cutting Ability:

Some forceps include cutting edges for monofilament or light braid. This is useful if you want one tool to handle both hook removal and quick line cutting.

Balance Between Length and Control:

Longer forceps (8”+) provide reach and leverage, but shorter ones give more precise control. Choose based on whether you prioritize reach or handling accuracy.

Look at Weight and Carry Options:

Lightweight models with lanyard holes or attachment clips are easier to carry and reduce the chance of losing them during fishing.

Feel free to reach out via the contact form below or email us directly with your requirements.

Our dedicated sales team will provide you with a comprehensive quotation within 24 hours.

We offer product samples for your testing and evaluation upon request.

Production will commence immediately upon order confirmation.

We guarantee secure and timely delivery to your specified location.

Material Selection:

RTI uses 420 and 3Cr13 stainless steel, both proven for corrosion resistance and strength in freshwater and saltwater. This ensures the jaws remain durable and reliable over time.

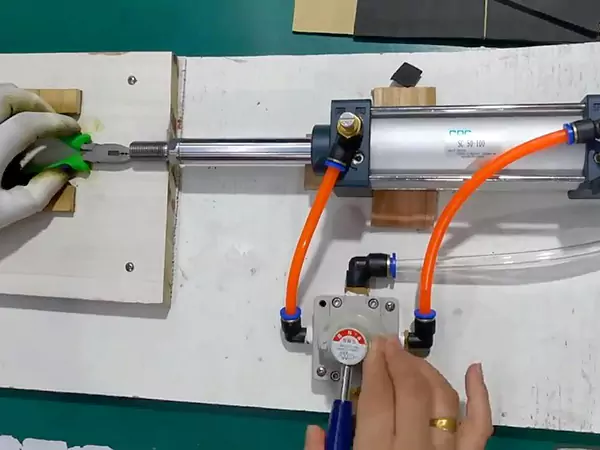

Blanking and Forging:

Steel sheets are stamped and forged under high-tonnage presses. This step provides consistent shape and strength as the base of each forceps.

Heat Treatment:

Forged parts are heat-treated to reach hardness around HRC 48–52. This prevents bending and keeps the jaws aligned after repeated use.

CNC Machining and Tip Finishing:

The jaws are machined for precise alignment and grip. Fine serrations are added so the forceps can hold hooks and lines securely without slipping.

Handle Forming and Surface Treatment:

Handles are shaped for ergonomic comfort. Depending on the model, they may include rubber coatings or polished finishes to improve grip and corrosion resistance.

Assembly:

Two halves of the forceps are joined and adjusted so the locking ratchet works smoothly. Each tool is checked for alignment and ease of operation.

Quality Inspection:

Finished products go through salt spray testing, grip strength checks, and repeated open-close cycles to confirm durability before packaging.

Packaging and Customization:

Forceps are packed in protective sleeves or paperboard packaging. OEM options, such as logos and custom finishes, are also available for distributors.

A: Fishing forceps are mainly used for removing hooks, handling lines, and pinching split shot weights. Many anglers also use them for small cutting tasks and knot tying assistance.

A: The 6.5” and 7.5” sizes are the most widely ordered because they balance precision with leverage. Other sizes are available depending on your target market.

A: Yes. Options include straight or curved jaws, with or without serrations, and different handle grips for comfort and control.

A: The MOQ depends on the level of customization, but generally starts at 500–1,000 pieces for OEM/ODM projects.

A: Each batch goes through strict quality checks, including hardness testing, corrosion resistance tests, and functional inspections of the jaws and locking mechanism.

A: For distribution and retail storage, keep forceps in dry, ventilated packaging. For end users, applying a light coat of oil before long-term storage helps prevent corrosion.

Copyright © 2010–2026 Weihai Yuanji Outdoor Products Co., Ltd.