A fishing line puller helps anglers quickly remove or tension fishing lines, ensuring smooth spooling and easy handling. It’s essential for both freshwater and saltwater fishing. Made from durable materials like aluminum and PVC-coated metals, these tools protect your lines from damage. With adjustable tension systems, anglers can spool or remove lines precisely, preventing frustration and keeping lines in perfect condition.

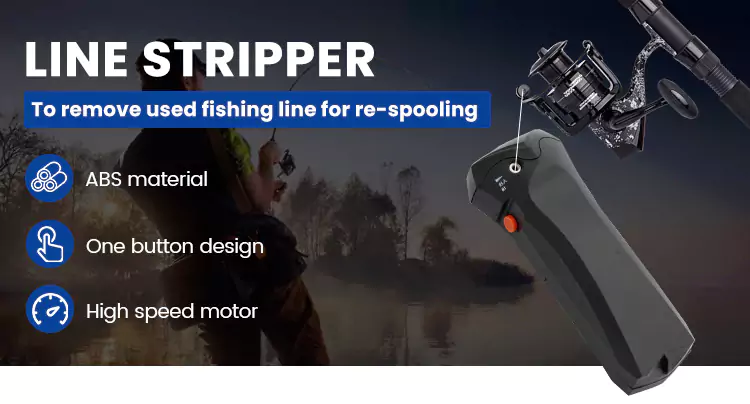

RTI offers a range of fishing line pullers to suit different needs. We provide adjustable aluminum pullers with locking systems, PVC-coated pullers for added protection, and multi-functional line stripper tools. Models like the Custom Tensioning Aluminum Line Pullers and Portable PVC Coating Line Pullers deliver durability, ease of use, and reliable performance. These tools meet the needs of casual anglers and fishing gear suppliers alike.

As a manufacturer in China, RTI specializes in custom fishing line pullers designed for your business. We offer bulk orders, OEM services, and custom branding to fit your requirements. Our products are crafted from high-quality materials to ensure long-lasting performance. With fast delivery and competitive pricing, RTI delivers dependable solutions that help your business grow.

Durable and Lightweight Aluminum Construction: RTI pullers are made from anodized aluminum for strength without extra weight. The anodized surface resists corrosion, making them reliable for long-term marine or freshwater use.

PVC-Coated Surfaces to Protect Fishing Line: Soft PVC coatings prevent abrasion and heat build-up, helping maintain line strength and reduce fraying during stripping or tensioning.

Adjustable Tension and Secure Locking: Built-in tension and locking systems ensure consistent, even spooling. This reduces line twist and improves efficiency for reel preparation or re-spooling tasks.

Manual and Powered Options Available: RTI offers both manual and battery-powered models. Motorized units improve speed for bulk work, while manual types offer simple operation for field or light-duty use.

Compatible with All Common Line Types: Each model is suitable for monofilament, fluorocarbon, and braided lines, covering a wide strength range from light to heavy-duty applications.

Match Material to Environment: For saltwater use, choose anodized aluminum or marine-grade stainless. For freshwater or light-duty work, aluminum or ABS is sufficient. The right material directly affects service life.

Select Proper Coating for Line Protection: PVC-coated jaws or soft sleeves prevent abrasion on braided or coated lines. Bare metal is fine for heavier mono but can wear softer lines.

Manual or Powered—Based on Workload: Manual pullers suit small batches or field use. Motorized models save time for high-volume re-spooling — check motor speed and power source compatibility.

Ensure Adjustable Tension and Secure Locking: A reliable tension and lock system keeps spooling consistent and prevents rework. Always test locking strength on samples.

Check Line Compatibility: Confirm the puller supports your line range (e.g., 2–80 lb). Matching the tool to your line type avoids slippage or crushing.

Evaluate Supplier Capabilities: Review the manufacturer’s OEM support, MOQ, and lead times. Custom branding and packaging often require higher MOQs or longer production cycles.

Feel free to reach out via the contact form below or email us directly with your requirements.

Our dedicated sales team will provide you with a comprehensive quotation within 24 hours.

We offer product samples for your testing and evaluation upon request.

Production will commence immediately upon order confirmation.

We guarantee secure and timely delivery to your specified location.

Material Selection and Control: RTI sources aluminum and stainless steel according to use — marine or freshwater. Proper alloy and surface finish ensure long service life and stable quality.

Precision Metal Processing: Aluminum parts are made by CNC machining, extrusion, or stamping to maintain tight tolerances and consistent dimensions across production batches.

Surface Treatment and Coating: Aluminum components are anodized for corrosion resistance, while PVC coating is applied to contact areas to protect fishing lines and improve grip.

Injection Molding for Plastic Parts: ABS housings and handles are produced by injection molding, ensuring precise fit, smooth finish, and cost-efficient repeatability.

Dedicated Assembly Lines: Mechanical and electrical assemblies are handled on separate lines for higher efficiency. Each stage is monitored for accuracy and traceability.

Functional Testing: All units undergo functional checks — including tension, locking, and motor operation — to confirm performance before packing.

Corrosion and Environmental Testing: Marine models are salt-spray tested per ASTM B117 to verify coating and surface durability under harsh environments.

Final Inspection and Packaging: Every product is visually and dimensionally inspected before shipment. OEM labels, barcodes, and packaging are applied according to buyer specifications.

A: MOQ varies by model and customization. Standard items can start from around 100 pcs, while custom tooling or printed packaging may require higher quantities. Contact sales for exact details.

A: Anodized aluminum and 316 stainless steel are recommended. Both resist corrosion and pitting in marine environments; PVC coatings add extra protection for contact areas.

A: Yes. RTI offers OEM/ODM services with options such as laser engraving, pad printing, or color anodizing. MOQ and lead time depend on the chosen decoration.

A: Yes. Motorized units typically cover a 2–80 lb range. Proper speed and contact design prevent slippage or damage — testing with your own line type is advised.

A: Each unit is inspected for dimensions, locking and tension accuracy, motor performance, and corrosion resistance (ASTM B117 for marine models).

A: Samples are available. Lead time depends on stock and customization — standard models ship faster, while custom tooling requires more time.

Copyright © 2010–2026 Weihai Yuanji Outdoor Products Co., Ltd.