50 – 499 pieces: $3.78

500 – 4999 pieces: $3.15

5000 – 49999 pieces: $3.06

>= 50000 pieces: $2.70

|

Material

|

Carbon Steel

|

|

Handle Material

|

TPE

|

|

Size

|

17.7*8cm

|

|

Split ring size

|

2.9 cm

|

Shipping Contact supplier to negotiate shipping details Enjoy On-time Dispatch Guarantee.

Payments Enjoy encrypted and secure payments.

Returns & Refunds Eligible for refunds within 30 days of receiving products.

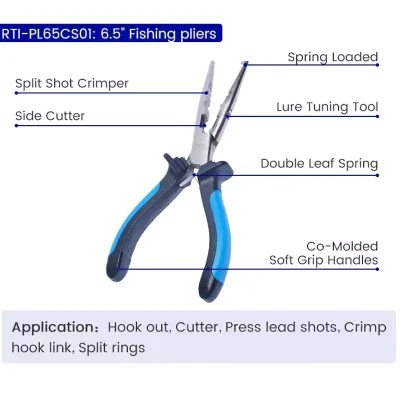

Carbon steel split ring pliers are compact tools for anglers. They open split rings, change hooks, crimp lead shots, and cut light leaders. With these functions, they improve rigging efficiency and reduce lure damage.

RTI’s 6.5″ Carbon Steel Split Ring Pliers are made from 45# high-strength carbon steel (AISI 1045). This material offers a strong balance of hardness, toughness, and durability for fishing use. The pliers feature a TPR co-molded handle that provides comfort and a secure grip, even when wet.

In addition, the tool integrates several functions. It includes a split ring opener, a side cutter for fishing lines, a split-shot crimper, and a double leaf spring for smooth one-hand operation.

For our B2B clients, the pliers are available with OEM logo marking, private-label packaging, and wholesale bulk supply. This flexibility allows brands and distributors to meet different market demands with confidence.

|

Product name

|

Fishing Plier

|

| Model Number |

RTI-PL65CS01

|

|

Material

|

Carbon Steel

|

|

Handle Material

|

TPR

|

|

Jaw Surface

|

Small Bevel

|

|

Color

|

Blue, Custom

|

|

Size

|

17.7*8cm

|

|

Split ring size

|

2.9cm

|

|

Application

|

Hook out, Cutter, Press lead shots, Crimp hook link

|

|

MOQ

|

500pcs

|

|

Package

|

Clam

|

|

Delivery Time

|

60 days

|

6.5″ length makes the pliers pocket- and tacklebox-friendly for anglers and field technicians, simplifying storage and transport for retail and bulk shipments.

Constructed from AISI 1045 (45#) carbon steel with TPR grips, the tool balances strength and corrosion resistance with a comfortable, durable handle suitable for both freshwater and light saltwater use.

TPR is overmolded onto a rigid core to create a textured, non-slip surface that improves grip security and reduces hand fatigue during repeated rigging operations.

An integrated split-ring opener speeds hook changes and reduces damage to split rings and lures, improving rigging efficiency for professional users and retailers.

Hardened cutter edges provide clean cuts on monofilament, fluorocarbon, and light leader wire, enabling neat rigging and fewer line failures during assembly or repairs.

Built-in crimp slot secures split shots without flattening or over-compressing the line, delivering consistent pressure for reliable weight attachment.

A front-jaw notch designed for lure eyelets lets users realign bent rings and restore factory action, preserving lure performance and reducing returns or complaints.

The dual-leaf spring ensures smooth, consistent opening for reliable one-hand operation, increasing speed and durability compared with single-spring designs.

A: The MOQ is usually 500pcs, depending on whether you need custom branding or standard bulk packing. For OEM projects with private-label packaging, the MOQ may be higher.

A: Yes. We support OEM branding by laser engraving or printing logos on the pliers. Handle colors and packaging designs can also be customized for bulk orders.

A: The pliers are produced with 45# carbon steel (AISI 1045) for durability and strength. We also offer stainless steel versions for customers who need stronger corrosion resistance in saltwater environments.

A: Yes. Samples are available. In most cases, the sample cost can be refunded after the first bulk order. Lead time for samples is usually 7–10 days.

A: The side cutter can cleanly cut monofilament up to 1.2 mm, fluorocarbon up to 0.8 mm, and light wire leaders up to 0.6 mm in diameter.

A: For standard stock pliers, production usually takes 50–60 days. Customized OEM orders may require additional time depending on packaging and branding requirements.

A: Yes. We can ship multiple plier models in the same order and prepare cartons according to your distribution plan. This helps distributors reduce shipping costs.

A: Each batch undergoes functional tests such as jaw alignment, spring tension, crimping strength, and cutter sharpness. For overseas clients, we can also arrange salt-spray tests or accept third-party inspections upon request.

Founded in 2002, RTL Company is a professional manufacturer of fishing tools specializing in R&D, production, sales, and service. We are committed to strict quality control and attentive customer service. Our experienced staff are always ready to discuss your requirements and ensure complete customer satisfaction.

We have a total of 59 patents, including 2 INVENTION patents, 23 UTILTY MODEL patents, 32 DESiGN patents, and 2 REGISTERED PATENTs in the USA.

Hot Selling MultifunctionalSmall Bevel Stainless Steel Split Ring Plier 5.5″ Fishing Pliers for Hook Out

Hot Selling MultifunctionalSmall Bevel Stainless Steel Split Ring Plier 5.5″ Fishing Pliers for Hook Out

Factory sale carbon steel nickle fishing pliers small bevel side cutter pliers split ring plier

Factory sale carbon steel nickle fishing pliers small bevel side cutter pliers split ring plier

Custom stainless steel tungsten steel cutter small bevel split ring plier fishing plier

Custom stainless steel tungsten steel cutter small bevel split ring plier fishing plier

Portable Multi-function 8.5cm Split Ring Plier Stainless Steel Line Cutter Pliers

Portable Multi-function 8.5cm Split Ring Plier Stainless Steel Line Cutter Pliers

Copyright © 2010–2026 Weihai Yuanji Outdoor Products Co., Ltd.