50 – 499 pieces: $3.30

500 – 4999 pieces: $2.75

5000 – 49999 pieces: $2.67

>= 50000 pieces: $2.40

|

Material

|

Stainless Steel

|

|

Jaw Surface

|

Smooth

|

|

Application

|

Braided line cutter

|

Shipping Contact supplier to negotiate shipping details Enjoy On-time Dispatch Guarantee.

Payments Enjoy encrypted and secure payments.

Returns & Refunds Eligible for refunds within 30 days of receiving products.

Braided line pliers are compact fishing tools built to cut braided line cleanly and perform basic tackle tasks. They usually combine a side cutter for braid, a tip for split rings, and a jaw for gripping hooks or small hardware. Anglers favor them for fast, clean cuts and quick one-hand use.

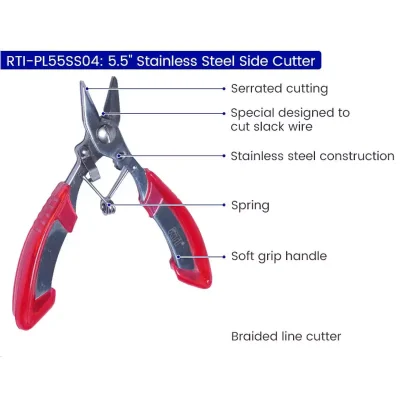

RTI’s 5.5″ braided line pliers are made of stainless steel and built for daily use. The tool uses micro-serrated blades to slice braided line without fraying. A spring keeps the pliers open for one-hand operation.

The lock system holds the tool closed for safe carry. Soft grip handles improve comfort during long use. RTI supplies these pliers to distributors and brands and offers OEM and wholesale options.

|

Product name

|

5.5″ Stainless Steel Side Cutter

|

| Model Number |

RTI-PL55SS04

|

|

Material

|

Stainless Steel

|

|

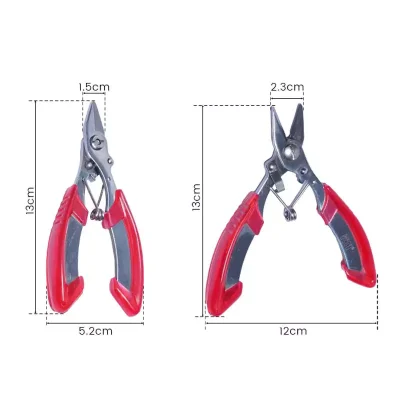

Size

|

13*5.2cm

|

|

Color

|

Red, Custom

|

|

Jaw Surface

|

Smooth

|

|

Application

|

Braided line cutter

|

|

Single package size

|

20X15X10 cm

|

|

Single gross weight

|

0.500 kg

|

Design & Tooling: Finalize CAD drawings and create production tooling for consistent parts.

Material Sourcing: Select corrosion-resistant stainless steel and quality grip materials from approved suppliers.

Blanking / CNC Machining: Cut or machine jaws, cutters, and body components to precise tolerances.

Heat Treatment & Hardening: Harden cutting edges for long wear and then temper for toughness.

Blade Grinding & Serration: Grind the side cutter profile. Add micro-serration for clean braid cutting.

Surface Finish & Passivation: Deburr and passivate stainless parts to improve corrosion resistance and appearance.

Handle Molding & Assembly: Mold soft grips, insert springs, fit hinges, and assemble the pliers.

Function & Quality Testing: Test cutting, locking, spring force, and handle bond. Inspect dimensions and finish.

Packaging & Labeling: Pack items for retail or bulk boxes for distributors. Apply custom labels on OEM orders.

A: Our minimum order quantity is 500 pcs. This applies to both standard wholesale orders and OEM/custom packaging projects.

A: Yes. We provide production or pre-production samples. Sample fees may apply, but they can be refunded against confirmed bulk orders.

A: The standard lead time is 50–60 days after order confirmation. Delivery time may vary slightly depending on order size and customization details.

A: Yes. We support OEM logos, private-label printing, blister cards, and custom cartons for wholesale distributors.

A: The pliers are made of stainless steel and treated for corrosion resistance. We recommend rinsing them with fresh water after saltwater use to extend service life.

A: Each batch is tested for cutting performance, spring action, lock reliability, and assembly strength. Random samples are also inspected for durability.

A: Yes. The micro-serrated cutter is effective on braided line, monofilament, and fluorocarbon lines.

A: We arrange worldwide shipments with full export documentation, including commercial invoices and packing lists. We also support customer-specified freight forwarders.

Founded in 2002, RTL Company is a professional manufacturer of fishing tools specializing in R&D, production, sales, and service. We are committed to strict quality control and attentive customer service. Our experienced staff are always ready to discuss your requirements and ensure complete customer satisfaction.

We have a total of 59 patents, including 2 INVENTION patents, 23 UTILTY MODEL patents, 32 DESiGN patents, and 2 REGISTERED PATENTs in the USA.

Wholesale Customized 100g Multifunction Aluminum Lure Fishing Tool Outdoor Fishing Pliers

Wholesale Customized 100g Multifunction Aluminum Lure Fishing Tool Outdoor Fishing Pliers

Wholesale Stainless Steel Multifunctional Straight Nose Fishing Pliers Grip Line Plier with TPR Handle

Wholesale Stainless Steel Multifunctional Straight Nose Fishing Pliers Grip Line Plier with TPR Handle

Multi-Functional Split Ring Fishing Pliers with Pliers Sleeve

Multi-Functional Split Ring Fishing Pliers with Pliers Sleeve

Light Weight Aluminium Saltwater Fishing Pliers Tungsten Steel Blade Fishing Pliers

Light Weight Aluminium Saltwater Fishing Pliers Tungsten Steel Blade Fishing Pliers

Copyright © 2010–2026 Weihai Yuanji Outdoor Products Co., Ltd.