10 – 100 pieces: $12.45

101 – 1000 pieces: $8.30

1001 – 3000pieces: $7.47

>= 3001 pieces: $7.06

|

Material

|

Stainless Steel

|

|

Blade

|

Tungsten steel blade

|

|

Weight

|

200g

|

|

Size

|

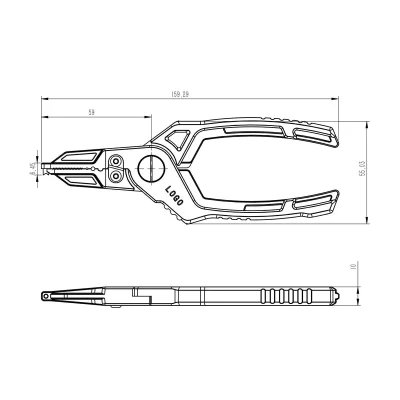

160*58*10mm

|

Shipping Contact supplier to negotiate shipping details Enjoy On-time Dispatch Guarantee.

Payments Enjoy encrypted and secure payments.

Returns & Refunds Eligible for refunds within 30 days of receiving products.

Saltwater fishing pliers are multi-function hand tools designed for saltwater angling. They open split rings, remove hooks, cut braided and PE lines, crimp sleeves and help with terminal work on boats and shore. Saltwater models use corrosion-resistant metals and replaceable cutters to survive harsh marine conditions.

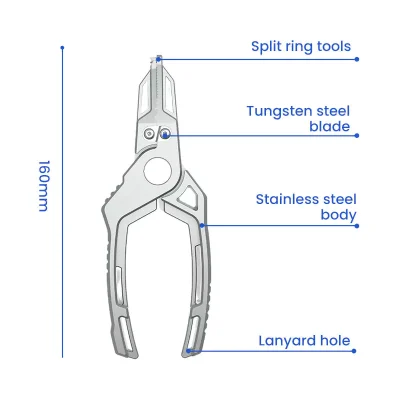

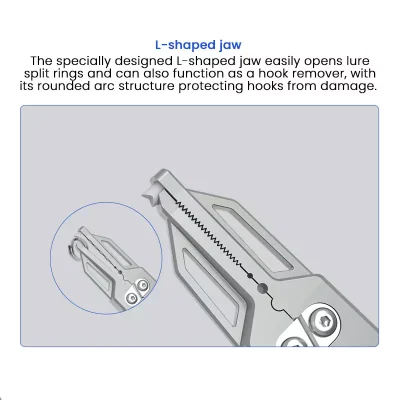

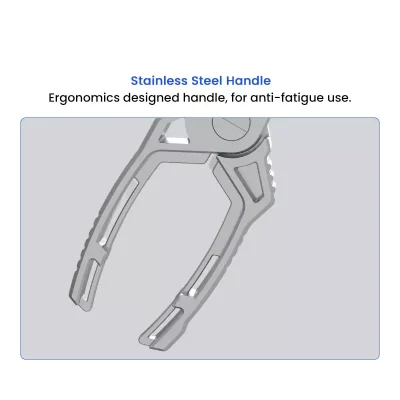

RTI’s 6.3″ stainless steel pliers combine a split-ring L-jaw, a replaceable tungsten cutter, and an interlocking nose for secure hold. They weigh ~200g and measure 160×58×10 mm. Spring-loaded handles and an ergonomic stainless body make one-hand use easier.

|

Product name

|

6.3” Stainless Steel Fishing Plier

|

|

Model Number

|

RTI-PL63SS02

|

|

Material

|

Stainless Steel

|

|

Blade

|

Tungsten steel blade

|

|

Weight

|

200g

|

|

Size

|

160*58*10mm

|

|

Single package size

|

25X12X3 cm

|

|

Single gross weight

|

0.500 kg

|

|

Feature

|

Split ring, lead tool, crimp tool

|

Each plier starts from a detailed CAD design that defines the L-shaped jaw angle, cutter placement, and handle geometry. The jaw gap tolerance is typically kept within ±0.05 mm to ensure smooth split-ring operation and accurate crimping.

Marine-grade 420 stainless steel is sourced from certified mills for corrosion resistance and strength. Tungsten steel cutter inserts and stainless rivets are purchased from approved suppliers to ensure hardness consistency (HRC 58–60 for cutters).

Plier blanks are stamped or hot-forged depending on the production batch. Forged jaws provide higher tensile strength and better impact resistance for heavy-duty saltwater use.

Critical surfaces — including the jaw tip, cutter slot, and interlocking teeth — are CNC-machined to exact tolerances. This step ensures precise alignment for smooth cutting and gripping performance.

Cutter and jaw zones undergo controlled heat treatment to improve edge retention and surface hardness. The process balances flexibility with strength to prevent brittle fractures during load.

The stainless parts are polished and passivated to remove surface impurities, then optionally treated with a protective anti-corrosion coating. This enhances saltwater resistance and extends service life.

Handles are finished for ergonomic comfort and anti-slip performance. For this stainless version, edges are rounded and brushed to a 240-grit finish, then assembled with a stainless leaf spring for reliable one-hand operation.

Each plier is fitted with the tungsten cutter, spring, and rivets. The cutter alignment and handle tension are manually checked to guarantee consistent action and cutting precision.

QC staff inspect every batch for dimensional accuracy, smooth jaw movement, and surface finish. Random units undergo functional tests including split-ring opening (≤1 mm gap), PE line cutting, and 48-hour salt spray tests for corrosion verification.

Products are packed according to order requirements — retail blister, color box, or custom bulk packaging for OEM clients. Each package includes product labeling and optional barcode printing.

After final inspection, goods are palletized and shipped according to client terms (FOB, CIF, or EXW). Export documentation includes HS code, packing list, and quality certificates upon request.

A: Custom packaging MOQ is 500 pieces. For plain bulk orders, smaller quantities may be possible — contact sales with your required volume.

A: Yes. We offer laser engraving and pad printing. Tell us your artwork file (vector format preferred) and required location for a quick quote.

A: Yes. The cutter is replaceable. We can supply spare blades or include extra blades in OEM kits.

A: Lead time depends on quantity and customization. Typical standard stock orders ship within 50–60 days. Custom OEM orders (logo/packaging) require longer; confirm with sales.

A: We perform internal QC tests (function, cutter performance, corrosion spot tests). For large OEM orders, we can support third-party inspection or tests on request.

A: We can supply spare tungsten blades and springs for buyers. Spare parts and reorder pricing depend on annual volumes.

Founded in 2002, RTL Company is a professional manufacturer of fishing tools specializing in R&D, production, sales, and service. We are committed to strict quality control and attentive customer service. Our experienced staff are always ready to discuss your requirements and ensure complete customer satisfaction.

We have a total of 59 patents, including 2 INVENTION patents, 23 UTILTY MODEL patents, 32 DESiGN patents, and 2 REGISTERED PATENTs in the USA.

Hot Sale Multifunctional Fishing Plier PVC Handle 6″ Carbon Steel Split Ring Plier

Hot Sale Multifunctional Fishing Plier PVC Handle 6″ Carbon Steel Split Ring Plier

Factory sale carbon steel nickle fishing pliers small bevel side cutter pliers split ring plier

Factory sale carbon steel nickle fishing pliers small bevel side cutter pliers split ring plier

Custom stainless steel tungsten steel cutter small bevel split ring plier fishing plier

Custom stainless steel tungsten steel cutter small bevel split ring plier fishing plier

Multi-Functional Split Ring Fishing Pliers with Pliers Sleeve

Multi-Functional Split Ring Fishing Pliers with Pliers Sleeve

Copyright © 2010–2026 Weihai Yuanji Outdoor Products Co., Ltd.