1 – 49 pieces: $11.70

50 – 299 pieces: $7.80

300 – 999 pieces: $7.02

>= 1000 pieces: $6.63

|

Material

|

Aluminium,Stainless steel

|

|

Color

|

Golden, Custom

|

|

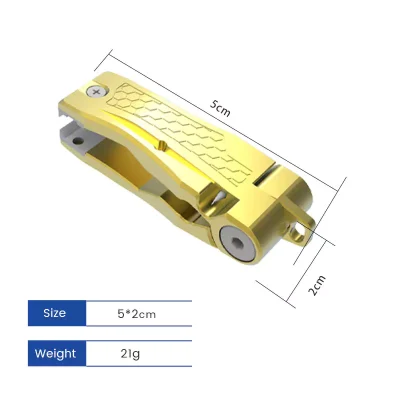

Size

|

5*2cm

|

|

Weight

|

21g

|

Shipping Contact supplier to negotiate shipping details Enjoy On-time Dispatch Guarantee.

Payments Enjoy encrypted and secure payments.

Returns & Refunds Eligible for refunds within 30 days of receiving products.

A mini fishing line cutter is a small hand tool. Anglers use it to cut fishing lines quickly and cleanly. It trims monofilament, fluorocarbon, and braided lines. The cutter is compact and easy to carry. It fits in tackle boxes or attaches to lanyards. Both recreational anglers and commercial suppliers use these tools in their kits.

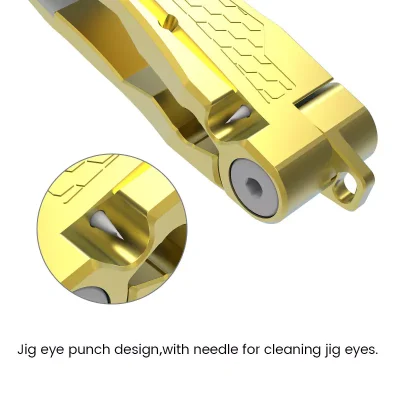

RTI designs its mini fishing line cutter with an aluminum body and removable stainless steel blades. The size is about 5 × 2 cm. The weight is around 21 g. It cuts both fine nylon and heavy braided lines. The tool includes a jig-eye punch and a cleaning needle. Magnets near the blades keep the clipper ready for quick use.

The compact design works well for retail displays, bulk packaging, and OEM private-label programs. RTI also offers custom branding, packaging, and bulk pricing. Contact our sales team for details.

| Material | Aluminium,Stainless steel |

| Color | Golden, Custom |

| Size | 5*2cm |

| Weight | 21g |

| Function |

Cut fine nylon line |

| Position |

Ocean Boat Fishing, Ocean Beach Fishing, Lake, Reservoi. |

| Single package size | 10X5X3 cm |

| Single gross weight | 0.500 kg |

| Feature |

|

Durable aluminum housing: Aluminum keeps weight low and resists deformation. It gives a premium feel while reducing overall product weight for retailers.

Replaceable stainless steel blades: Removable blades make service and replacement simple. Blades hold sharpness and cut braided and monofilament lines reliably.

Long blade life guarantee: Blades are hardened and ground for extended life. This reduces replacement costs for distributors and end users.

Fast access with magnetic design: Integrated magnets help keep the clipper ready. Quick access saves time during rigging and reduces handling steps.

Jig-eye punch & cleaning needle: Adds small but useful functions for lure and jig maintenance.

RTI engineers prepare 2D/3D drawings and finalize tooling requirements. For OEM projects, packaging and label mockups are also developed.

We source anodizable aluminum billets and stainless steel blade stock from trusted suppliers. Materials are inspected to meet hardness and corrosion-resistance standards.

Aluminum bodies are CNC-machined or stamped to precise tolerances. Each part is deburred and cleaned before moving to finishing.

Stainless steel blades are hardened and precision-ground. Edges are sharpened to ensure clean cuts through braided, nylon, and monofilament lines.

Aluminum bodies are anodized or color-coated. This step improves durability and protects against saltwater corrosion.

Blades, magnets, springs, and optional accessories (lanyards, jig-eye punch, or cleaning needle) are fitted into the housing. Each unit is assembled to ensure smooth operation.

Each batch undergoes dimensional checks and visual inspection. Random samples are tested for cutting efficiency and cycle life on different line types.

Finished units are packed in standard color boxes or custom OEM packaging. Barcodes and labels are added according to client requirements.

A final QC review confirms assembly, packaging, and labeling standards. Products are then packed into master cartons and prepared for FOB or EXW shipment.

A: The body is aluminum and the cutting jaws are stainless steel. The tool also includes a needle and a jig-eye punch.

A: Yes. The stainless jaws are removable, and spare blades can be ordered for easy replacement.

A: Yes. The sharpened blades cut braided, monofilament, and fine nylon lines cleanly.

A: Yes. Samples are available for evaluation. Fees and lead times depend on the sample type and printing requirements.

A: The minimum order quantity is 500 pieces. Contact RTI with your specifications for details on custom packaging and branding.

A: Standard delivery time is 50–60 days after order confirmation. OEM projects may require additional time depending on customization.

Founded in 2002, RTL Company is a professional manufacturer of fishing tools specializing in R&D, production, sales, and service. We are committed to strict quality control and attentive customer service. Our experienced staff are always ready to discuss your requirements and ensure complete customer satisfaction.

We have a total of 59 patents, including 2 INVENTION patents, 23 UTILTY MODEL patents, 32 DESiGN patents, and 2 REGISTERED PATENTs in the USA.

Hot Sale Durable Fly Fishing Line Nippers Multi-Function Fishing Clipper

Hot Sale Durable Fly Fishing Line Nippers Multi-Function Fishing Clipper

Hot Sell Fly Fishing Tool Line Cutter Nipper Black Ceramic Clipper with Hook Sharpener

Hot Sell Fly Fishing Tool Line Cutter Nipper Black Ceramic Clipper with Hook Sharpener

Outdoor Fishing Stainless Steel Line End Cutter Clipper For Fishing

Outdoor Fishing Stainless Steel Line End Cutter Clipper For Fishing

Aluminium Stainless Steel Fly Fishing Line Nipper Cutter Clipper with Hook Eye Cleaner Pin

Aluminium Stainless Steel Fly Fishing Line Nipper Cutter Clipper with Hook Eye Cleaner Pin

Copyright © 2010–2026 Weihai Yuanji Outdoor Products Co., Ltd.