1 – 49 pieces: $10.20

50 – 299 pieces: $6.80

300 – 999 pieces: $6.12

>= 1000 pieces: $5.78

|

Material

|

Aluminum Alloy

|

|

Blade

|

Tungsten steel blade

|

|

Weight

|

100g

|

|

Color

|

Blue, Custom

|

Shipping Contact supplier to negotiate shipping details Enjoy On-time Dispatch Guarantee.

Payments Enjoy encrypted and secure payments.

Returns & Refunds Eligible for refunds within 30 days of receiving products.

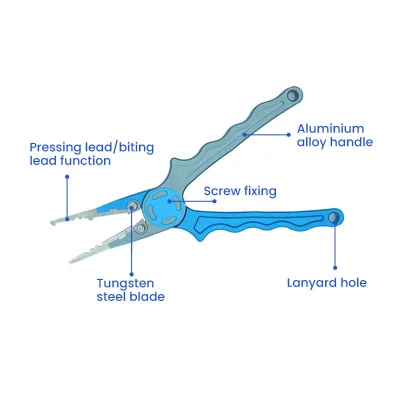

Outdoor fishing pliers are compact tools designed for common tackle tasks: opening split rings, removing hooks, cutting braided or mono lines, and crimping or pressing small leads. Anglers keep them on a lanyard or in a pouch for fast access. Good pliers resist corrosion, cut cleanly, and stay light for long days on the water.

RTI’s Outdoor Fishing Pliers are built from aluminum alloy and weigh 100g. They combine a tungsten-steel cutting blade with a pressed lead / biting lead function and an aluminum alloy handle. The design includes screw fixing and a lanyard hole.

RTI offers OEM branding, custom packaging, and wholesale options for distributors and private-label customers.

|

Product name

|

Fishing plier

|

|

Model Number

|

RTI-PL70AL05

|

|

Material

|

Aluminum Alloy

|

| Blade |

Tungsten steel blade

|

|

Weight

|

100g

|

|

Color

|

Blue, Custom, OEM

|

|

Single package size

|

25X15X10cm

|

|

Single gross weight

|

1.000 kg

|

|

Customized packaging

|

Min. order: 500 pieces

|

A: Standard MOQ for custom packaging is 500 pieces. Smaller MOQ may be possible for repeat customers—contact sales for exact terms.

A: Yes. RTI offers logo stamping or laser engraving on metal and custom-printed boxes. Provide vector artwork and confirm proof before mass production.

A: Typical lead time for custom orders is 50–60 days after order confirmation and sample approval. Rush production may be available for an extra fee.

A: The aluminum alloy and treated blade provide moderate resistance. For full marine use, recommend rinsing after saltwater exposure and consider titanium or stainless models for heavy saltwater use.

A: Yes. RTI can print custom retail boxes, insert hang tags, and apply barcodes or UPC/EAN labels per buyer requests.

A: We run cutting performance checks, joint torque inspections, and random corrosion checks. Each shipment includes a QC report on request.

Founded in 2002, RTL Company is a professional manufacturer of fishing tools specializing in R&D, production, sales, and service. We are committed to strict quality control and attentive customer service. Our experienced staff are always ready to discuss your requirements and ensure complete customer satisfaction.

We have a total of 59 patents, including 2 INVENTION patents, 23 UTILTY MODEL patents, 32 DESiGN patents, and 2 REGISTERED PATENTs in the USA.

Wholesale 7 inch Titanium Fishing Pliers Multi-function Split Ring Pliers

Wholesale 7 inch Titanium Fishing Pliers Multi-function Split Ring Pliers

Wholesale Carbon Steel Joint Bent Long Nose Pliers 45 Degree Crucible Tongs Fishing Pliers

Wholesale Carbon Steel Joint Bent Long Nose Pliers 45 Degree Crucible Tongs Fishing Pliers

Durable Multi-function Carbon Steel Plier 6″ Special Split Ring Plier

Durable Multi-function Carbon Steel Plier 6″ Special Split Ring Plier

Factory sale carbon steel nickle fishing pliers small bevel side cutter pliers split ring plier

Factory sale carbon steel nickle fishing pliers small bevel side cutter pliers split ring plier

Copyright © 2010–2026 Weihai Yuanji Outdoor Products Co., Ltd.