100 – 500 pieces $6.23

501 – 1000 pieces$4.15

1001 – 3000 pieces$4.03

>= 3001 pieces $3.53

| Blade Material | Stainless steel |

| Handle Material | Wooden |

| Handle Size | 14cm |

| Blade Size | 6″ |

| Weight |

110g |

Shipping Contact supplier to negotiate shipping details Enjoy On-time Dispatch Guarantee.

Payments Enjoy encrypted and secure payments.

Returns & Refunds Eligible for refunds within 30 days of receiving products.

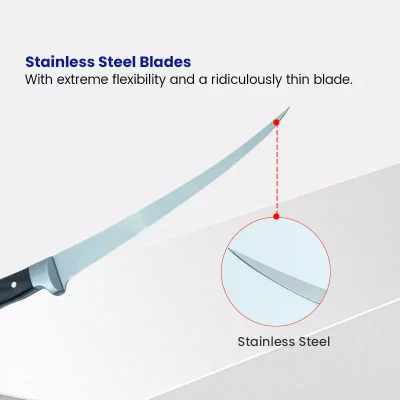

A 6 inch flexible fillet knife has a long, thin blade that bends slightly. This flexibility helps you follow the fish’s bones and separate flesh cleanly. Flexible blades work best for delicate fish and close cuts. Tests and reviews show flexible blades usually give cleaner fillets and better control for fish work.

RTI’s 6 inch Flexible Fillet Knife pairs an ultra-thin 420 stainless steel blade with a full-tang build. The blade bends where you need it for precise bone-side cuts. The wooden handle is 14 cm long and includes a safety finger guard for secure grip. A leather sheath protects the blade in storage. At 110 g this knife is light and easy to control.

|

Product name

|

6” Flexible Fillet Knife

|

|

Blade Material

|

Stainless steel

|

|

Handle Material

|

Wooden

|

|

Handle Size

|

14cm

|

|

Blade Size

|

6″

|

|

Weight

|

110g

|

A: MOQ depends on packaging and customization. For standard retail packaging MOQ is typically lower; for OEM/private-label expect higher MOQ. Contact sales with your packaging and order forecast.

A: Yes. We support OEM/ODM, private-label packaging and custom branding. Provide your artwork and specs for a quote.

A: Blade: 420 stainless steel. Handle: hardwood (14 cm) with a safety finger guard. A leather sheath is included.

A: We use corrosion-resistant stainless steel and finish treatments. We also perform salt-spray checks on production samples.

A: Yes — 6″, 7″ and 8″ sizes are available. Size availability depends on order quantity and stock.

A: Lead time varies by order size, customization and current factory schedule. For a tailored lead time please share quantity, packaging and any tooling needs.

A: The blade is fixed (full-tang) and not designed for field replacement. We offer quality guarantees for manufacturing defects; warranty terms depend on order type (retail vs. OEM).

A: Yes. We offer preproduction and production samples. Sample policy depends on the model and customization requested.

Founded in 2002, RTL Company is a professional manufacturer of fishing tools specializing in R&D, production, sales, and service. We are committed to strict quality control and attentive customer service. Our experienced staff are always ready to discuss your requirements and ensure complete customer satisfaction.

We have a total of 59 patents, including 2 INVENTION patents, 23 UTILTY MODEL patents, 32 DESiGN patents, and 2 REGISTERED PATENTs in the USA.

Custom OEM/ODM Outdoors Fish Cutting Fillet Knife Non-stick Coating 4″ Bait Knife Stainless Steel Fishing Knife

Custom OEM/ODM Outdoors Fish Cutting Fillet Knife Non-stick Coating 4″ Bait Knife Stainless Steel Fishing Knife

Hot sale 7.5″ kitchen fish knife fillet stainless steel cutting fish fillet k

Hot sale 7.5″ kitchen fish knife fillet stainless steel cutting fish fillet k

Professional Non-Slip Handles 6 Inch Fish Filleting Knife

Professional Non-Slip Handles 6 Inch Fish Filleting Knife

New Design Fishing Knife Stainless Steel 6 inch Fish Fillet Knife Fishing Knife With PP Handle

New Design Fishing Knife Stainless Steel 6 inch Fish Fillet Knife Fishing Knife With PP Handle

Copyright © 2010–2026 Weihai Yuanji Outdoor Products Co., Ltd.