5- 49 pieces: $10

50 – 499 pieces: $8.10

500 – 999 pieces: $7.10

>= 1000 pieces: $6.10

|

Blade Material

|

Stainless Steel

|

|

Handle Material

|

TPR

|

|

Weight

|

140g

|

|

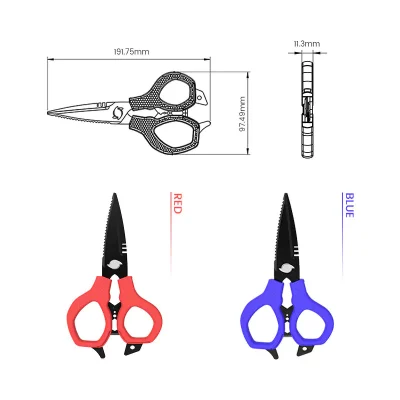

Size

|

16.8*8*1CM

|

Shipping Contact supplier to negotiate shipping details Enjoy On-time Dispatch Guarantee.

Payments Enjoy encrypted and secure payments.

Returns & Refunds Eligible for refunds within 30 days of receiving products.

Multi Function Fishing Scissors are purpose-built shears for anglers and fishing professionals. They cut monofilament, fluorocarbon and braided lines. They also combine extra tools — crimpers, bottle openers, lanyard holes and more — in one compact unit. These scissors speed up common tasks at the boat, pier, or dock.

RTI’s Detachable Multi-Function & Heavy Duty Fishing Scissors use high-grade 5CR15 stainless steel blades with a titanium coating. The soft TPR handle fits gloved hands and offers a secure grip. Blades detach for fast cleaning. The tool targets distributors, brands and OEM buyers who need reliable, customizable fishing shears in bulk.

| Product name | Detachable Multi Function&Heavy Duty Fishing Scissors |

| Model Number |

RTI-LS50 |

| Blade Material | Stainless Steel |

| Handle Material | TPR |

| Size | 16.8*8*1CM |

| Weight | 140g |

| Color |

Red, Blue, Custom |

| Single Package Size | 25X10X10 cm |

| Single Gross Weight | 1.000 kg |

| Usage | Fishing, Outdoor Sports, Outdoor Activities |

| Features |

High quality 5CR15 stainless steel, titanium coated. |

Stainless Steel Blade:

High quality 5CR15 stainless steel blade. Titanium coating improves corrosion resistance and lowers surface wear. Blades hold a sharp edge and are easy to resharpen.

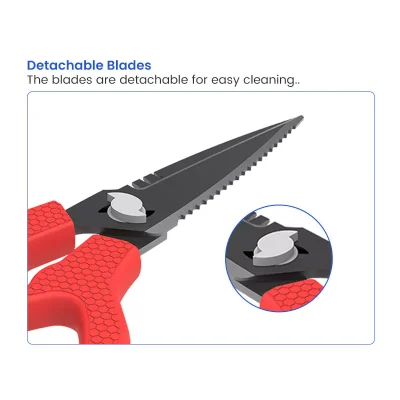

Detachable Blades:

Quick-release blade design for deep cleaning, sharpening, or replacement. Reduces downtime and extends service life.

Fishing Regulator:

Built-in regulator (line guide) helps position line for steady, accurate cuts and prevents slippage during trimming.

Serrated Kerf:

Micro-serrated edge bites braided and mono lines for clean, reliable cuts. Works well on tough synthetic fibers.

Soft Rubber (TPR) Handle:

Ergonomic TPR handle with oversized thumb hole. Comfortable grip even with gloves on. Non-slip in wet conditions.

Crimper:

Integrated crimper for split shots, sleeves or terminal crimps. Saves time by keeping two tasks in one tool.

Lanyard Holes:

Dual lanyard attachment points for secure retention on belts, vests or lifejackets.

Bottle Opener:

Practical bottle opener built into the handle. Useful for crews and recreational use on the boat.

Easy Field Maintenance:

The detachable blade system simplifies cleaning and sharpening.

Made for Braided Lines:

Serrated cutting geometry holds modern braided lines and prevents fraying.

Durable Corrosion Control:

5CR15 steel with a titanium finish resists rust and pitting in saltwater environments.

Comfort Under Load:

Large thumb hole and soft TPR grip reduce hand fatigue during prolonged use.

Multi-Tool Value:

Combining cutter, crimper and bottle opener reduces the number of items in a kit.

OEM / Custom-Ready:

Designed to accept custom logos, printed packaging and private labeling.

A: We provide logo laser-etching, custom packaging, hang cards, and private label OEM packs. MOQ and lead time depend on the customization level.

A: MOQ varies by order type. For most custom scissor orders we support 100–500 pcs. Exact MOQ depends on printing and packaging specs.

A: Yes. The micro-serrated kerf and blade geometry are tuned to bite and cut braided fibers without fraying. Perform line tests on samples before bulk production.

A: Yes, we provide pre-production samples. Standard sample lead time is typically 7–14 days depending on whether custom marking or tooling is required.

A: We test cutting performance on mono, fluoro and braided lines, verify crimper function, conduct corrosion spot tests, and check assembly torque and handle bond strength.

A: We support bulk cartons, retail blister cards, and OEM boxes. We handle export paperwork for bulk orders.

A: Yes. We can share CAD drawings, DWG/PDF dimension sheets and sample photos once we discuss customization and NDA if needed.

Founded in 2002, RTL Company is a professional manufacturer of fishing tools specializing in R&D, production, sales, and service. We are committed to strict quality control and attentive customer service. Our experienced staff are always ready to discuss your requirements and ensure complete customer satisfaction.

We have a total of 59 patents, including 2 INVENTION patents, 23 UTILTY MODEL patents, 32 DESiGN patents, and 2 REGISTERED PATENTs in the USA.

Sea Fishing Braid Line Cutter Scissors Generic Ceramic Fishing Line Scissors

Sea Fishing Braid Line Cutter Scissors Generic Ceramic Fishing Line Scissors

Multi-functional Stainless Steel Kitchen Scissors Shredded Scallion Cut Herb Spices Scissors Triple Blade Worm Scissors

Multi-functional Stainless Steel Kitchen Scissors Shredded Scallion Cut Herb Spices Scissors Triple Blade Worm Scissors

Multi-purpose Stainless Steel Double Blade Chopped Worm Herb Scissors with PP Handle

Multi-purpose Stainless Steel Double Blade Chopped Worm Herb Scissors with PP Handle

Hot Selling Stainless Steel Blade Small Fishing Folding Scissor Foldable Scissors

Hot Selling Stainless Steel Blade Small Fishing Folding Scissor Foldable Scissors

Copyright © 2010–2026 Weihai Yuanji Outdoor Products Co., Ltd.