HOME / PRODUCTS / Fishing Line Clippers / Foldable Fly Fishing Tool Line Cutter Nipper Stainless Steel Fishing Line Clipper

Foldable Fly Fishing Tool Line Cutter Nipper Stainless Steel Fishing Line Clipper

50 – 499 pieces: $1.69

500 – 4999 pieces: $1.30

5000 – 49999 pieces: $1.26

>= 50000 pieces: $1.10

|

Material

|

Stainless Steel

|

|

Color

|

Black

|

|

Funtion

|

>Cutting Knife >”Line Pick” hook.

>Large thumb bar. |

|

Packaging

|

Blister ,OEM

|

Shipping

Contact supplier to negotiate shipping details Enjoy On-time Dispatch Guarantee.

Payments

Enjoy encrypted and secure payments.

Returns & Refunds

Eligible for refunds within 30 days of receiving products.

A foldable fishing line clipper is a compact cutting tool designed for anglers. It cuts monofilament, fluorocarbon, and light braid. The blade folds into the handle for safe, pocketable storage. Many models add small tools — like a line pick or lure tuning knife — to handle common on-boat tasks. These clippers save time at the knot and keep tackle organized.

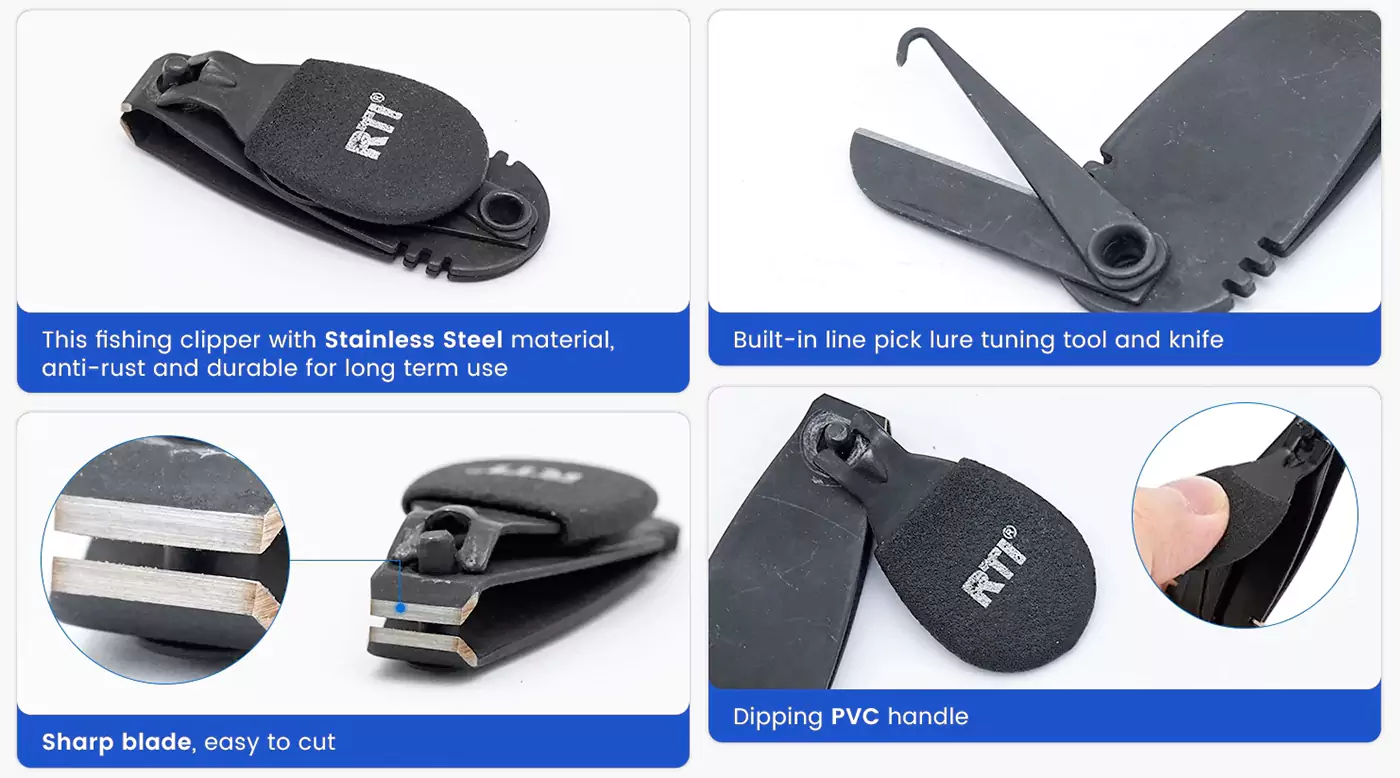

RTI’s clipper uses stainless steel for long service life. The body folds to protect the blade and the user. It measures about 6.3 × 2.5 cm and comes in black. The tool combines a sharp cutting blade, a built-in line pick (for clearing knots and picking eyes), and a small tuning knife. The handle has a PVC dip for a secure grip.

Product Specifications

|

Producct Name

|

Stainless Steel Clipper

|

|

Material

|

Stainless Steel

|

|

Color

|

Black

|

|

Size

|

6.3*2.5cm

|

|

Funtion

|

>Cutting Knife

>”Line Pick” hook.

>Large thumb bar. |

|

Packaging

|

Blister ,OEM

|

Foldable Fishing Line Clipper Product Display

Advantages of Foldable Line Clipper

- Durable Stainless Steel Build: Made from stainless steel, the clipper resists rust and stands up to repeated use in both freshwater and saltwater conditions.

- Sharp and Reliable Cutting Edge: The precision-ground blade cuts fishing line quickly and cleanly, reducing time spent on knot preparation.

- Multi-Function Tools in One Unit: Includes a built-in line pick for clearing hook eyes, a lure tuning tool, and a small knife for quick adjustments.

- Comfortable PVC-Dipped Handle: The dipped grip provides a non-slip surface, ensuring steady handling even when hands are wet.

Foldable Line Clipper Manufacturing Process

- Product design & engineering: Drawings are made for the foldable body and blade. OEM projects include packaging and logo layout.

- Material sourcing: Stainless steel and PVC coating are sourced from approved suppliers. Each batch is checked for hardness and rust resistance.

- Stamping & blade forming: Steel sheets are stamped to size. Blades are heat-treated and sharpened for clean cutting.

- Handle dipping: Handles are dipped in PVC for a non-slip grip and comfort.

- Assembly: Blades, line pick, knife, and folding parts are assembled. The fold and lock are adjusted for smooth use.

- Quality control: Samples are tested for sharpness, folding strength, and corrosion resistance.

- Packaging: Units are packed in blister cards or OEM cartons with labels and barcodes.

- Final inspection & shipping: Finished products are checked, boxed in master cartons, and shipped under agreed terms.

Q1: What materials are used in this foldable line clipper?

A: The clipper is made of stainless steel with a PVC-dipped handle. It includes a cutting blade, line pick, and small knife.

Q2: Can the blade or parts be replaced?

A: The cutting edge is fixed for durability. For long-term supply, RTI offers replacement units in bulk rather than loose blades.

Q3: Is it suitable for braided line?

A: Yes. The sharpened stainless blade cuts monofilament, fluorocarbon, and light braided lines.

Q4: Can I request samples before placing a bulk order?

A: Yes. Samples are available. Lead time is about 7–14 days, depending on whether you need custom printing or OEM packaging.

Q5: What is the minimum order quantity for OEM or custom packaging?

A: The MOQ is 500 pieces. Custom branding, logo printing, and blister packaging can be arranged on request.

Q6: What is the delivery time for wholesale orders?

A: Standard lead time is about 45 days after confirmation. Custom OEM projects may require additional time.

- Assurance Agreement: Enjoy a 5% discount for eachweek of delayed delivery.

- OEM & ODM: We support small orders to inspectquality (once before packaging,once before shipment) and supportOEM design.

- Free Samples: Free samples are provided.

- Create Molds: For a single product, if the orderquantity exceeds 5000PCS, wecan create molds to customizeyour own style.

- Photos & Videos: We support customers with high-defnition photos and videos.

- Online Service: 24/7 after-sales service.