5 – 49 pieces: $30

50 – 499 pieces: $24

500 – 999 pieces: $23

>= 1000 pieces: $22

|

Material

|

Aluminum + tungsten steel cutter

|

|

Handle Material

|

Aluminum

|

|

Weight

|

85g

|

|

Size

|

17*6*1cm

|

|

Color

|

Blue

|

Shipping Contact supplier to negotiate shipping details Enjoy On-time Dispatch Guarantee.

Payments Enjoy encrypted and secure payments.

Returns & Refunds Eligible for refunds within 30 days of receiving products.

A titanium fishing plier pairs corrosion-resistant titanium at the working end with a lighter handle body. These pliers are built for saltwater use, where rust resistance matters. Common functions include removing hooks, opening split rings, cutting leaders, and crimping. For professional use, titanium tips last longer and reduce maintenance compared with plain steel.

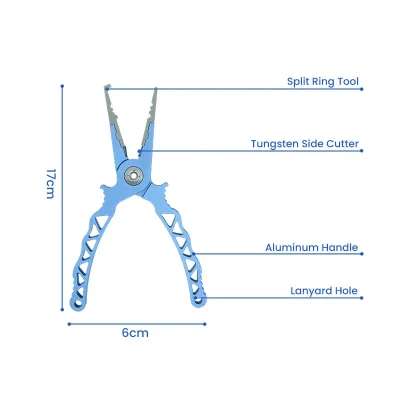

RTI’s 7 inch Titanium Fishing Plier combines an aluminum handle with a titanium working tip and a tungsten side cutter. It measures about 17×6×1 cm and weighs ~85 g — light for easy carry and package-friendly for wholesale. Key features include a split-ring tool, tungsten side cutter for braided line, ergonomic anti-slip handle, spring-loaded action, and a lanyard hole for secure attachment.

|

Product name

|

Titanium Fishing Plier

|

| Model Number |

RTI-PL70AL08

|

|

Material

|

Aluminum + tungsten steel cutter

|

|

Handle Material

|

Aluminum

|

|

Jaw Surface

|

Small Bevel

|

|

Color

|

Blue

|

|

Size

|

17*6*1cm

|

|

Weight

|

85g

|

|

Single package size

|

25X15X10 cm

|

|

Single gross weight

|

1.000 kg

|

Material Specification & Procurement:

We source anodizable aluminum alloys for handles and titanium-grade tips (e.g., Ti-6Al-4V or equivalent) for corrosion resistance. Tungsten carbide (WC) grades are used for the side cutter. Suppliers are pre-approved and batch-traceable.

CNC Machining & Tip Fabrication:

CNC lathes and mills machine jaw geometry and tip profiles to tight tolerances. Titanium parts are machined using tooling and feeds suited for titanium alloys to avoid work hardening.

Edge Preparation & Cutter Production:

Tungsten carbide inserts or hardened cutter blanks are ground and polished to cutting tolerances for clean braid cuts. Cutters undergo finish grinding and edge inspection.

Anodizing & Surface Treatments:

Aluminum handles receive anodizing for color and corrosion resistance. Titanium tips may be passivated or bead-blasted to a consistent finish. Surface treatment improves longevity in marine environments.

Assembly & Fit Adjustment:

Skilled assemblers fit jaws, springs, and cutters, then adjust jaw alignment and spring tension. Split-ring tool geometry is set and function-tested.

Quality Control & Salt Spray Testing:

Random samples go through dimensional checks, cutter-performance tests, and salt spray (corrosion) testing per agreed inspection standards. Any deviation triggers corrective action.

Packaging, Custom Branding & Final Inspection:

For OEM/wholesale orders, we apply logo engraving or laser marking, custom color anodizing, and pack per buyer’s spec (carded blister, bulk box, or retail-ready box). Final QC verifies packaging, weight, and labeling.

A: The MOQ is 500 pieces per model. We accept smaller sample orders for testing before bulk production.

A: Yes. We can laser-engrave logos, apply custom anodized colors, and offer private-label packaging based on your artwork.

A: The handle is aluminum, the jaw tip is titanium, and the side cutter is tungsten carbide for cutting braided line.

A: Yes. The titanium tip and anodized handle prevent rust in saltwater conditions. Extra coatings can be added if needed.

A: Standard lead time is 60 days after order confirmation and artwork approval.

A: Yes. We can provide samples for quality checking. Sample cost will be credited to your bulk order.

A: Each batch is checked for cutting performance, jaw alignment, and corrosion resistance. Inspection reports are available if required.

A: Yes. We can make other sizes, handle shapes, or tool combinations based on your drawings or samples.

Founded in 2002, RTL Company is a professional manufacturer of fishing tools specializing in R&D, production, sales, and service. We are committed to strict quality control and attentive customer service. Our experienced staff are always ready to discuss your requirements and ensure complete customer satisfaction.

We have a total of 59 patents, including 2 INVENTION patents, 23 UTILTY MODEL patents, 32 DESiGN patents, and 2 REGISTERED PATENTs in the USA.

Wholesale Customized 100g Multifunction Aluminum Lure Fishing Tool Outdoor Fishing Pliers

Wholesale Customized 100g Multifunction Aluminum Lure Fishing Tool Outdoor Fishing Pliers

Durable Multi-function Carbon Steel Plier 6″ Special Split Ring Plier

Durable Multi-function Carbon Steel Plier 6″ Special Split Ring Plier

Multi Function Carbon Steel Fishing Line Pliers 5″ Hook Out Fishing Pliers Split Rings Pliers

Multi Function Carbon Steel Fishing Line Pliers 5″ Hook Out Fishing Pliers Split Rings Pliers

Hot Selling MultifunctionalSmall Bevel Stainless Steel Split Ring Plier 5.5″ Fishing Pliers for Hook Out

Hot Selling MultifunctionalSmall Bevel Stainless Steel Split Ring Plier 5.5″ Fishing Pliers for Hook Out

Copyright © 2010–2026 Weihai Yuanji Outdoor Products Co., Ltd.